Forklift Operator, Construction Vehicle Driver... How to Avoid Pain While Operating Heavy Machinery?

Why do construction vehicle drivers suffer from back pain?

Why does driving a construction vehicle cause back pain?

Various health risks are associated with operating construction equipment:

- • Prolonged sitting posture, known to be harmful to the human body.

- • Shocks caused by uneven terrain where construction machinery operates: potholes, bumps, rocks, etc.

- • Machinery vibrations, a major aggravating factor in the development of MSDs (musculoskeletal disorders) and widely present in the construction sector.

Combined, these factors increase the risk of developing pain, making construction work one of the most affected industries by MSDs.

Why is prolonged sitting posture painful?

Sitting puts various strains on the human body. Our bodies are naturally subject to gravity, which causes slight compression over the course of the day. In a seated position, this pressure is concentrated on the coccyx/sacrum, leading to discomfort or pain, and may worsen existing conditions.

Remaining in one position for too long leads to muscle tension as the body constantly performs micro-contractions to maintain posture. This applies to prolonged sitting but also to any static posture in general, which is why movement is recommended to limit pain.

Poor posture also promotes pain: many people fail to use the seat backrest and tend to slump forward. This compresses the abdomen, pinches the intervertebral discs forward, and disrupts the natural curvature of the spine. In this position, the discs can no longer absorb shocks properly, increasing the body's exposure to shocks and vibrations.

What are the risks of shocks and vibrations when driving construction equipment?

While operating vehicles, whether personal or work-related, the body is exposed to an added strain: shocks and vibrations.

Known as high peaks, shocks result from uneven ground: construction vehicles often run over surfaces filled with potholes, bumps, and rocks. Vibrations, or low peaks, refer to the micro-vibrations generated by the machinery itself.

These shocks and micro-vibrations spread through the body and are recognized as aggravating factors in the development of musculoskeletal disorders.

In construction vehicles, shocks and vibrations are even more significant due to uneven terrain and the engines of the machines.

How to prevent pain when operating construction equipment?

Equip yourself to prevent pain when operating machinery

Given the various strains endured while operating machinery, it's essential to be equipped to prevent pain.

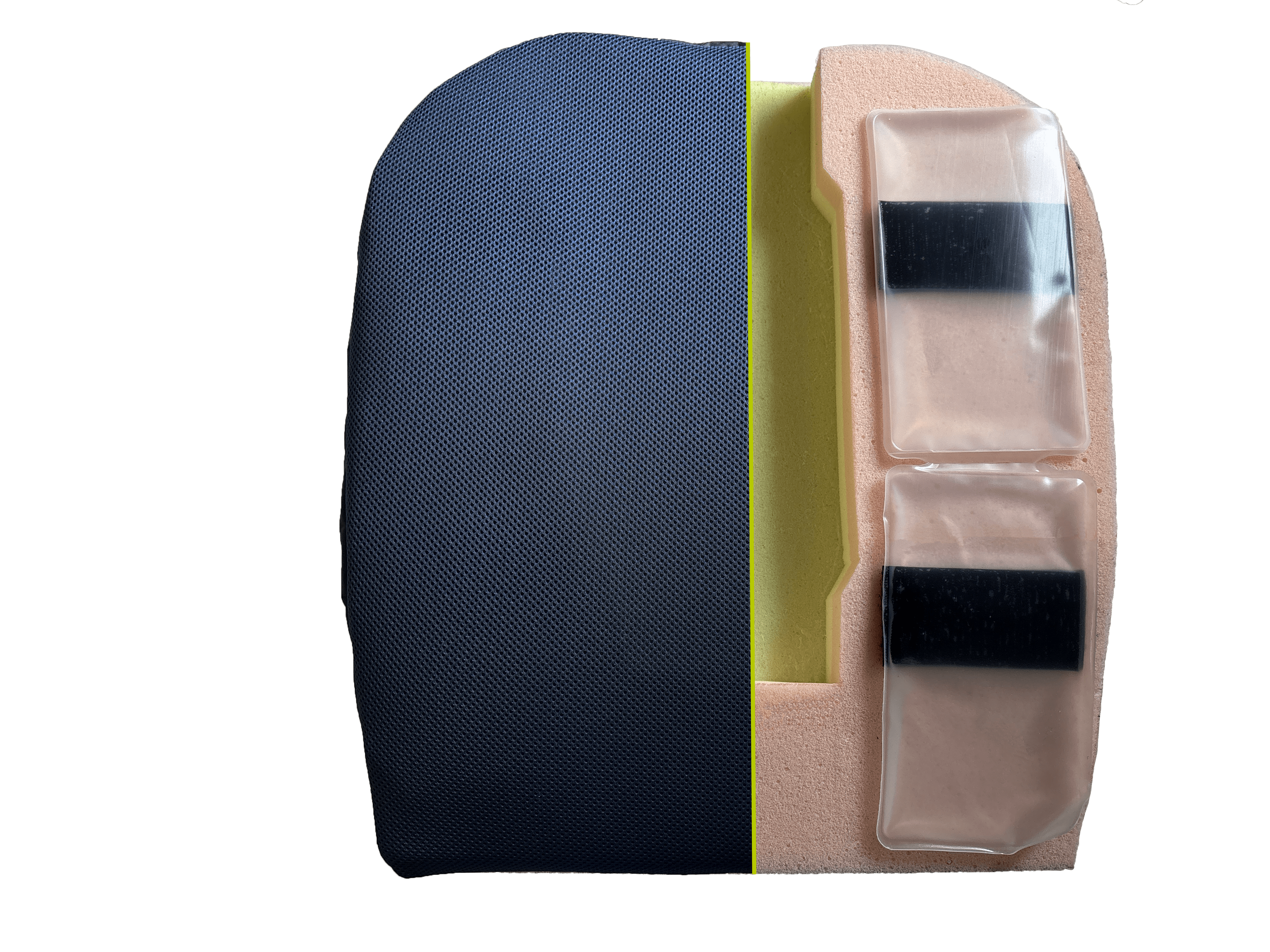

The goal is to improve driving posture to adopt a position of minimal discomfort and reduced strain on the body. To achieve this, using a triangular seat cushion helps elevate the pelvis. This opens the abdomen and prevents compression and forward disc pinching when slouching.

Another critical factor to address is vibration. Using an anti-vibration cushion protects the body and improves seating comfort. Improving comfort reduces the need for compensatory postures like leaning to one side to alleviate discomfort.

Correcting posture and protecting against vibrations can significantly reduce the risk of pain and musculoskeletal disorders. Other ergonomic equipment for machinery can complement the seat cushion for full-body protection.

How to equip yourself when you already have back pain?

It’s even more important to be properly equipped if you suffer from conditions like sciatica, a herniated disc, or a vertebral compression fracture. These conditions and the resulting pain (back pain, buttock pain) can be worsened by the aforementioned constraints.

In addition to the features mentioned earlier, your seat cushion should be adapted to your condition. For back issues, a coccyx-relief cushion helps reduce pressure on the coccyx and sacrum while seated. This coccyx cut-out also prevents seat vibrations from traveling up the spine via the coccyx.

To complement your seat cushion, we recommend using a backrest for heavy machinery vehicles to provide full protection and shield the back from vibrations.

For carpal tunnel syndrome issues, an armrest for machinery helps isolate the forearm from vibrations and reduce pressure from resting on the hard surface of the machine’s armrest.